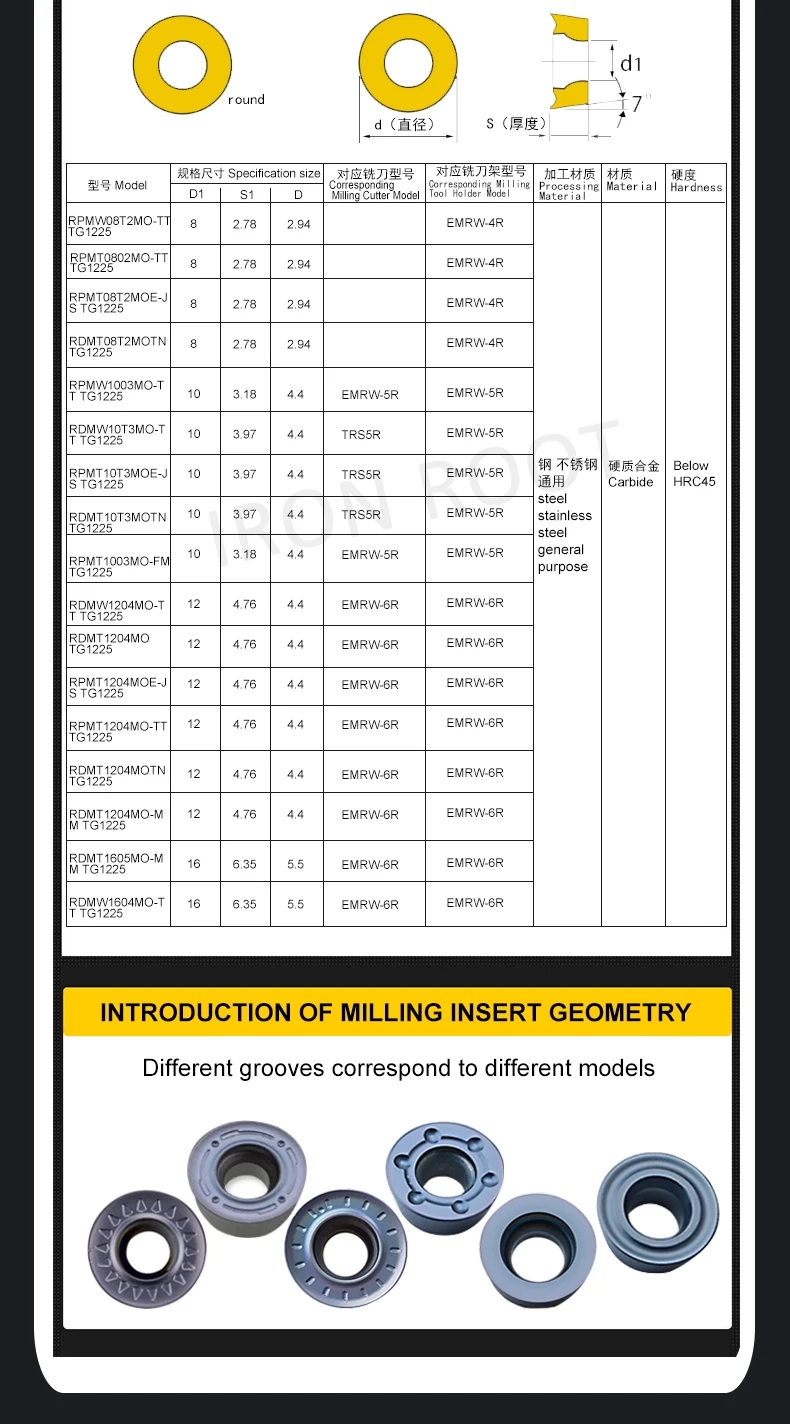

RDMW Indexable Carbide Insert

Some of the key benefits of RDMW carbide inserts:

Precision pressed: These inserts are precision pressed to ensure dimensional accuracy and consistency

Optimized for roughing: RDMW inserts are an excellent choice for heavy roughing due to their rugged design

and strength

Wide material compatibility: They perform well on a wide range of materials, including steel, stainless steel, and

Reinforced cutting edge: Designed with a reinforced cutting edge, they provide increased edge security and

longer tool life

Customizable solutions: Available in a variety of geometries, chipbreakers, and grades, they can be customized

to specific machining requirements

About the product

The RDMW milling carbide insert is designed for multi-material machining, featuring a 15° side clearance angle and is compatible with Walter®, Dijet® and other industry supplier milling cutters. It boasts a reinforced cutting edge for increased edge security and is coated with PVD TiAlN+ for excellent heat and oxidation resistance across a wide range of ISO P, M, K, and S materials. This insert is precision pressed and is an excellent choice for roughing operations, especially in steel and cast iron. It offers superior performance and value, making it a universal, first-choice grade for a variety of workpiece materials and mixed production.

Material & Construction

Key Features

Applications

Lifespan

Quality Assurance

Manufactured under strict quality control, including dimensional inspection, hardness testing (91–93 HRA), and coating adhesion checks. Each batch is validated for performance consistency, ensuring reliability in critical machining applications.

RDMW Carbide Inserts: Performance Parameters

Material & Coating Specifications

Dimensional & Geometric Parameters

Machining Performance Metrics

Durability & Lifespan

Compatibility & Operational Limits

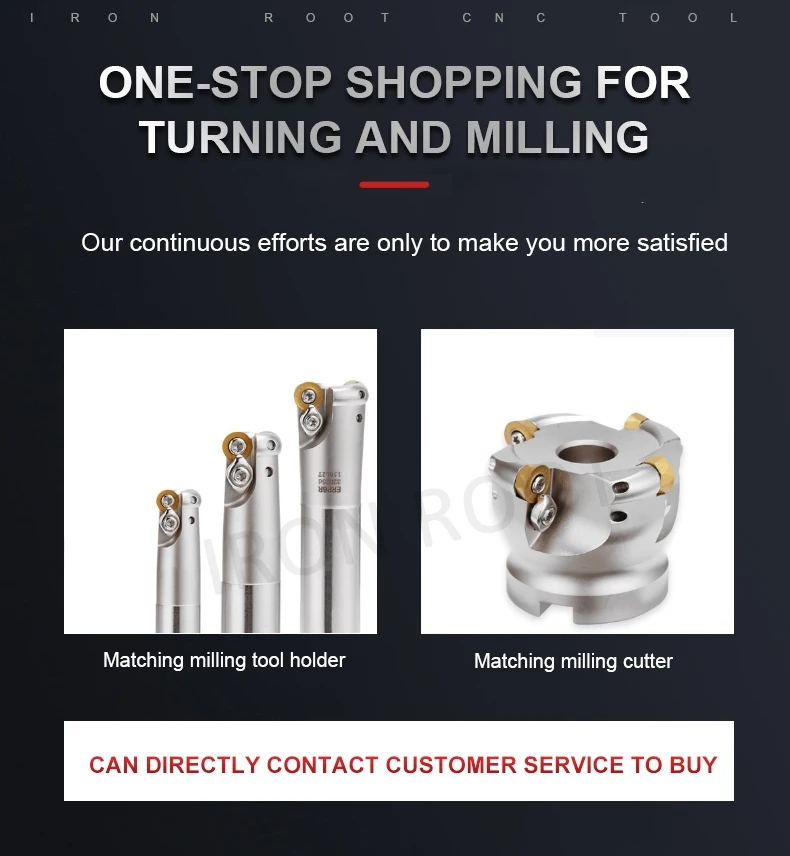

About Our Company

Jinan Xinxin Trading Co., Ltd. is a company specializing in a full range of turning tools, milling tools, holemaking tools, carbide cutting tools, machine tool accessories and

other products. At the same time, we accept non-standard product customization and provide perfect tooling solutions for the machining and manufacturing industry.

After years of development, our company firmly believe in the concept of integrity-based, with high-quality service so that the company's products are exported to

Europe, the Middle East, South America, Southeast Asia throughout the world's more than 40 industrialized countries and regions, won the majority of domestic

and foreign customers to support and trust.

Jinan Xinxin Trading Co., Ltd. was founded in 2012, is an excellent comprehensive imported CNC cutting tools agents in Shandong, the company firmly believe in

the concept of good faith, with high quality and attentive service. The company believes in the concept of good faith, with high quality and attentive service. For

the various machining enterprises to supply the world's famous brands of imported CNC cutting tools, machining center tools.

Company Brands

Our company brand IRONROOT series products, with excellent quality and perfect service, strive to reduce the cost of using tools for you.

Main products

Our company, as an important link in the machining field, is following and driving its whole system to run. Our distribution of products has become increasingly systematized, mainly including: Sandvik Coromant sandvikcoromant, Seco, Walter, Kennametal Group Kennametal, Mitsubishi MITSUBISHI, Sumitomo Sumitomo, Kyocera Sholette Kyocera CERATIP, Toshiba, Daijie, Hitachi Tools HITACHI TOOL, ISCAR ISCAR, German cobalt collar Guehring, TEGUTEC TAEGUTEC, KORLOY KORLOY and so on.

Domestic brands: Zhuzhou Diamond Brand, Zigong Great Wall Brand, Zhuzhou Jingcheng Brand, Chengdu Yingge, Ha Yigong, Harbin Tool Factory, Southwest Tools, Chengqi Tools, Shaanxi Cemented Carbide, Zhuzhou Cemented Carbide, Guizhou Yihai, Shanghai Tool Factory and a series of domestic and foreign well-known brands of manufacturers of various types and specifications of CNC blades, Metal lathe tools CNC cutting tools, whole tools, machine-clamped blades, welded blades, toolposts, shank, holder, tungsten steel slats, bars. Tungsten steel slats and bars.

At present, our company's product range includes turning tools, milling tools, drilling tools, tooling systems, carbide cutting tools, machine tool accessories and so on.

Our Customer Reviews

Our products are exported to various countries,milling insert including the United States, the United Kingdom, Spain, Italy, Belgium, France, Germany, etc., and are deeply loved and supported by users in these countries. Metal lathe tools

Thank you very much for watching

Welcome to inquire about the prices, and we will provide you with the best service.

Website: https://www.ironrootcnctools.

Whatsapp/Mobile: +86 13969129141

Email: lronroot190@gmail.com