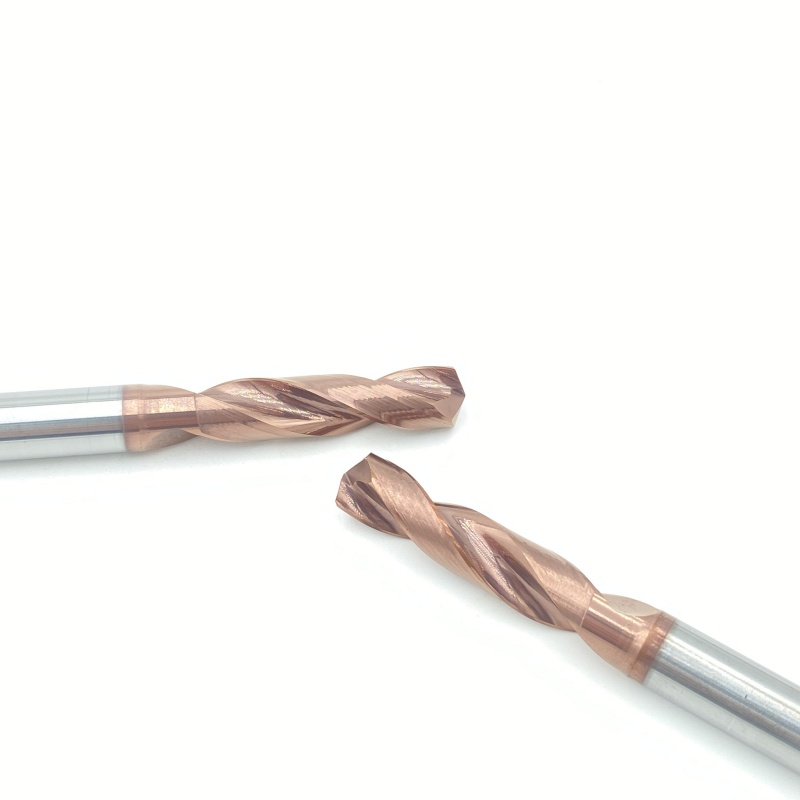

58° Carbide Fixed Shank Twist Drill Industrial Grade Precision Drilling Tool

1. Material and structural advantages

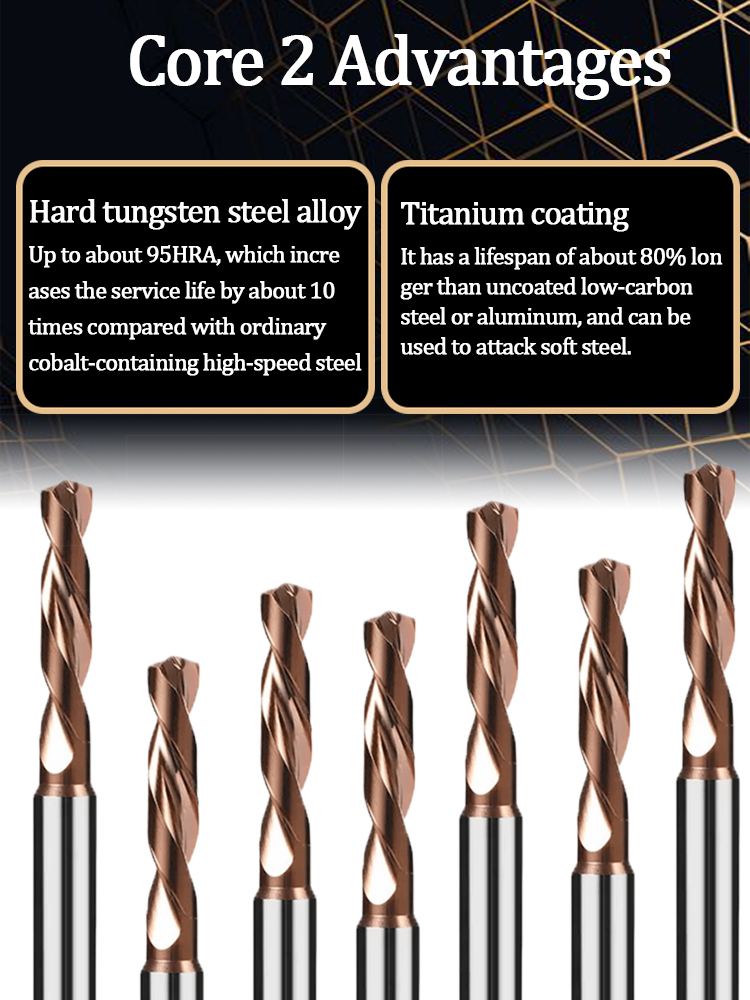

Using carbide material, the wear resistance is significantly higher than that of ordinary high-speed steel drill bits, and the service life is extended by 3-5 times.

Special coating technology (such as cobalt-containing and super-hard coating) further improves the ability to resist high-temperature oxidation and is suitable for high-speed cutting.

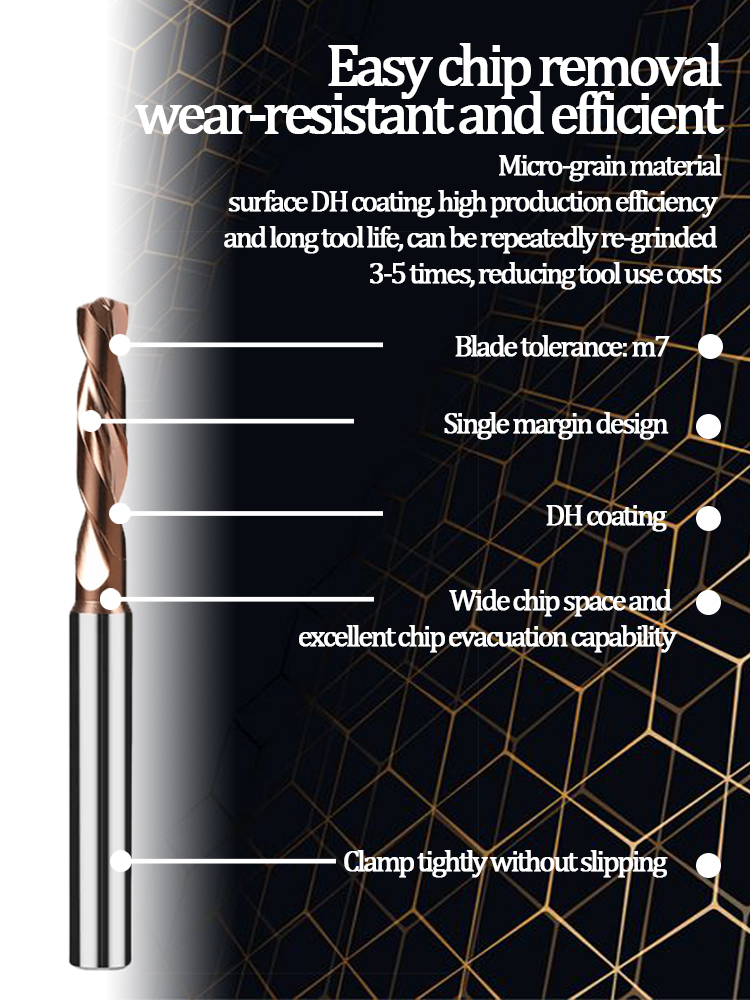

The helix angle is optimized to 36°-38° (about 30° for ordinary drill bits), and the chip removal resistance is reduced by more than 40%, reducing drilling pollution and heat accumulation.

The nano-grinding process forms a sharp cutting edge, and with a large chip removal groove space, it avoids chip blockage in deep hole processing.

2. Performance and processing advantages

The thickened drill core design (drill core thickness reaches 15%-20% of the diameter) improves rigidity and supports deep hole processing of more than 5 times the diameter (5D), with a hole deflection of ≤0.02mm.

The fixed handle structure (such as D3/D4 handle) is suitable for CNC machine tool spindles, reduces vibration, and improves centering accuracy by 30%.

The design of no chisel edge or re-grinding chisel edge reduces the axial cutting force by 50% and improves the roundness of the drill hole (up to IT8 level).

The variable spiral angle technology is suitable for different materials such as stainless steel and titanium alloy, and the hole diameter tolerance can be controlled at ±0.01mm.

3. Application scenario advantages

Covering difficult-to-process materials such as stainless steel, titanium alloy, and high-temperature alloy (such as GH4169), the cutting speed can reach 60-120m/min (ordinary drill bits are only 20-40m/min).

The special groove design supports the processing of brittle materials such as PCB boards and aluminum alloys, and the hole wall roughness is ≤Ra1.6μm.

4. Economic advantages

A single drill bit can be re-grinded 7-10 times, reducing the frequency of tool replacement.

High-efficiency processing reduces labor costs, for example, the efficiency is increased by more than 3 times when processing stainless steel.

Carbide fixed-shank twist drills can maintain stable physical properties in cutting environments. The drill body adopts an integrated carbide molding process, and a chip groove with a helix angle of 36°-38° is formed through nano-grinding technology, which improves the chip removal efficiency by more than 40% compared to traditional high-speed steel drills. The fixed-shank structure (such as D3/D4 shank) achieves high-precision matching with the machine tool spindle, and the thickened drill core design (core thickness of 15%-20% of the diameter) ensures that the axial deflection is ≤0.02mm during deep hole processing.

The drill is suitable for difficult-to-process materials such as stainless steel, titanium alloy (such as TC4), and high-temperature alloy (such as GH4169). The cutting speed can reach 60-120m/min, especially in stainless steel processing, it can withstand a torque load of 120N·m]. The deep hole processing capability exceeds the 5D limit, and the internal cooling channel design can directly deliver the cutting fluid to the tip of the tool, reducing the cutting temperature by about 30%. The special chisel edge grinding technology reduces the axial cutting force by 50%, and can avoid hole burrs and deformation in thin plate processing.

A single drill bit can be reground and regenerated 7-10 times, which reduces the life cycle cost of traditional high-speed steel tools by 60%. For micro-processing scenarios such as PCB boards, the minimum diameter can be as small as 0.08mm, and the variable helix angle design can achieve precision processing of the aperture tolerance of ±0.005mm]. The environmentally friendly cemented carbide material complies with RoHS standards and has a recycling rate of over 95%.

| Brand | IRON ROOT |

| Name | Carbide fixed shank twist drill |

| Features | 3x diameter fixed shank |

| Package | 1 piece per box |

| Processing hardness | 58° |

| Processing material | Applicable to various materials |

| Coating | Titanium coating |

| 58° 3D fixed handle drill | |||||||

Model | Model | Model | Model | ||||

| D3*15*20*36*d6*62 | D6.7*22.7*34*36*d8*79 | D10.4*37.5*55*45*d12*102 | D14*36.5*60*45*d14*107 | ||||

| D3.1*14.8*20*36*d6*62 | D6.8*22.6*34*36*d8*79 | D10.5*37.3*55*45*d12*102 | D14.1*41.3*65*48*d16*115 | ||||

| D3.2*14.6*20*36*d6*62 | D6.9*22.4*34*36*d8*79 | D10.6*37.2*55*45*d12*102 | D14.2*41.1*65*48*d16*115 | ||||

| D3.3*14.4*20*36*d6*62 | D7*22.2*34*36*d8*79 | D10.7*37*55*45*d12*102 | D14.3*40.9*65*48*d16*115 | ||||

| D3.4*14.3*20*36*d6*62 | D7.1*29.1*41*36*d8*79 | D10.8*36.8*55*45*d12*102 | D14.4*40.8*65*48*d16*115 | ||||

| D3.5*14.1*20*36*d6*62 | D7.2*28.9*41*36*d8*79 | D10.9*36.7*55*45*d12*102 | D14.5*40.6*65*48*d16*115 | ||||

| D3.6*13.9*20*36*d6*62 | D7.3*28.7*41*36*d8*79 | D11*36.5*55*45*d12*102 | D14.6*40.4*65*48*d16*115 | ||||

| D3.7*13.8*20*36*d6*62 | D7.4*28.6*41*36*d8*79 | D11.1*36.3*55*45*d12*102 | D14.7*40.3*65*48*d16*115 | ||||

| D3.8*17.6*24*36*d6*66 | D7.5*28.4*41*36*d8*79 | D11.2*36.2*55*45*d12*102 | D14.8*40.1*65*48*d16*115 | ||||

| D3.9*17.4*24*36*d6*66 | D7.6*28.2*41*36*d8*79 | D11.3*36*55*45*d12*102 | D14.9*39.9*65*48*d16*115 | ||||

| D4*17.3*24*36*d6*66 | D7.7*28*41*36*d8*79 | D11.4*35.8*55*45*d12*102 | D15*39.8*65*48*d16*115 | ||||

| D4.1*17.1*24*36*d6*66 | D7.8*27.9*41*36*d8*79 | D11.5*35.7*55*45*d12*102 | D15.1*39.6*65*48*d16*115 | ||||

| D4.2*16.9*24*36*d6*66 | D7.9*27.7*41*36*d8*79 | D11.6*35.5*55*45*d12*102 | D15.2*39.4*65*48*d16*115 | ||||

| D4.3*16.8*24*36*d6*66 | D8*27.5*41*36*d8*79 | D11.7*35.3*55*45*d12*102 | D15.3*39.3*65*48*d16*115 | ||||

| D4.4*16.6*24*36*d6*66 | D8.1*33.4*47*40*d10*89 | D11.8*35.2*55*45*d12*102 | D15.4*39.1*65*48*d16*115 | ||||

| D4.5*16.4*24*36*d6*66 | D8.2*33.2*47*40*d10*89 | D11.9*35*55*45*d12*102 | D15.5*38.9*65*48*d16*115 | ||||

| D4.6*16.3*24*36*d6*66 | D8.3*33*47*40*d10*89 | D12*34.8*55*45*d12*102 | D15.6*38.8*65*48*d16*115 | ||||

| D4.7*16.1*24*36*d6*66 | D8.4*32.9*47*40*d10*89 | D12.1*39.6*60*45*d14*107 | D15.7*38.6*65*48*d16*115 | ||||

| D4.8*19.9*28*36*d6*66 | D8.5*32.7*47*40*d10*89 | D12.2*39.5*60*45*d14*107 | D15.8*38.4*65*48*d16*115 | ||||

| D4.9*19.8*28*36*d6*66 | D8.6*32.5*47*40*d10*89 | D12.3*39.3*60*45*d14*107 | D15.9*38.3*65*48*d16*115 | ||||

| D5*19.6*28*36*d6*66 | D8.7*32.4*47*40*d10*89 | D12.4*39.1*60*45*d14*107 | D16*38.1*65*48*d16*115 | ||||

| D5.1*19.4*28*36*d6*66 | D8.8*32.2*47*40*d10*89 | D12.5*39*60*45*d14*107 | D16.5*45.2*73*48*d18*123 | ||||

| D5.2*19.3*28*36*d6*66 | D8.9*32*47*40*d10*89 | D12.6*38.8*60*45*d14*107 | D16.9*44.6*73*48*d18*123 | ||||

| D5.3*19.1*28*36*d6*66 | D9*31.9*47*40*d10*89 | D12.7*38.6*60*45*d14*107 | D17*44.4*73*48*d18*123 | ||||

| D5.4*18.9*28*36*d6*66 | D9.1*31.7*47*40*d10*89 | D12.8*38.5*60*45*d14*107 | D17.5*43.6*73*48*d18*123 | ||||

| D5.5*18.7*28*36*d6*66 | D9.2*31.5*47*40*d10*89 | D12.9*38.3*60*45*d14*107 | D17.9*42.9*73*48*d18*123 | ||||

| D5.6*18.6*28*36*d6*66 | D9.3*31.4*47*40*d10*89 | D13*38.1*60*45*d14*107 | D18*42.7*73*48*d18*123 | ||||

| D5.7*18.4*28*36*d6*66 | D9.4*31.2*47*40*d10*89 | D13.1*38*60*45*d14*107 | D18.3*48.2*79*50*d20*131 | ||||

| D5.8*18.2*28*36*d6*66 | D9.5*31*47*40*d10*89 | D13.2*37.8*60*45*d14*107 | D18.5*47.9*79*50*d20*131 | ||||

| D5.9*18.1*28*36*d6*66 | D9.6*30.9*47*40*d10*89 | D13.3*37.6*60*45*d14*107 | D18.9*47.2*79*50*d20*131 | ||||

| D6*17.9*28*36*d6*66 | D9.7*30.7*47*40*d10*89 | D13.4*37.5*60*45*d14*107 | D19*47*79*50*d20*131 | ||||

| D6.1*23.7*34*36*d8*79 | D9.8*30.5*47*40*d10*89 | D13.5*37.3*60*45*d14*107 | D19.3*46.5*79*50*d20*131 | ||||

| D6.2*23.6*34*36*d8*79 | D9.9*30.3*47*40*d10*89 | D13.6*37.1*60*45*d14*107 | D19.5*46.2*79*50*d20*131 | ||||

| D6.3*23.4*34*36*d8*79 | D10*30.2*47*40*d10*89 | D13.7*37*60*45*d14*107 | D19.9*45.5*79*50*d20*131 | ||||

| D6.4*23.2*34*36*d8*79 | D10.1*38*55*45*d12*102 | D13.8*36.8*60*45*d14*107 | D20*45.4*79*50*d20*131 | ||||

| D6.5*23.1*34*36*d8*79 | D10.2*37.8*55*45*d12*102 | D13.9*36.6*60*45*d14*107 | |||||

| D6.6*22.9*34*36*d8*79 | D10.3*37.7*55*45*d12*102 | ||||||