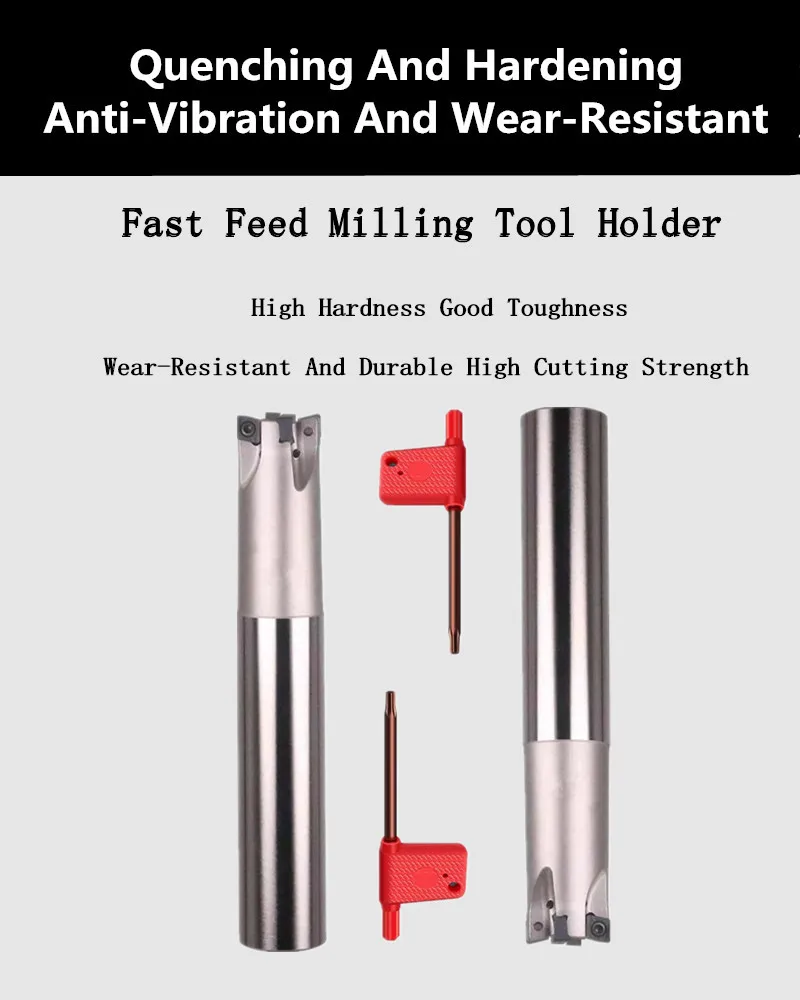

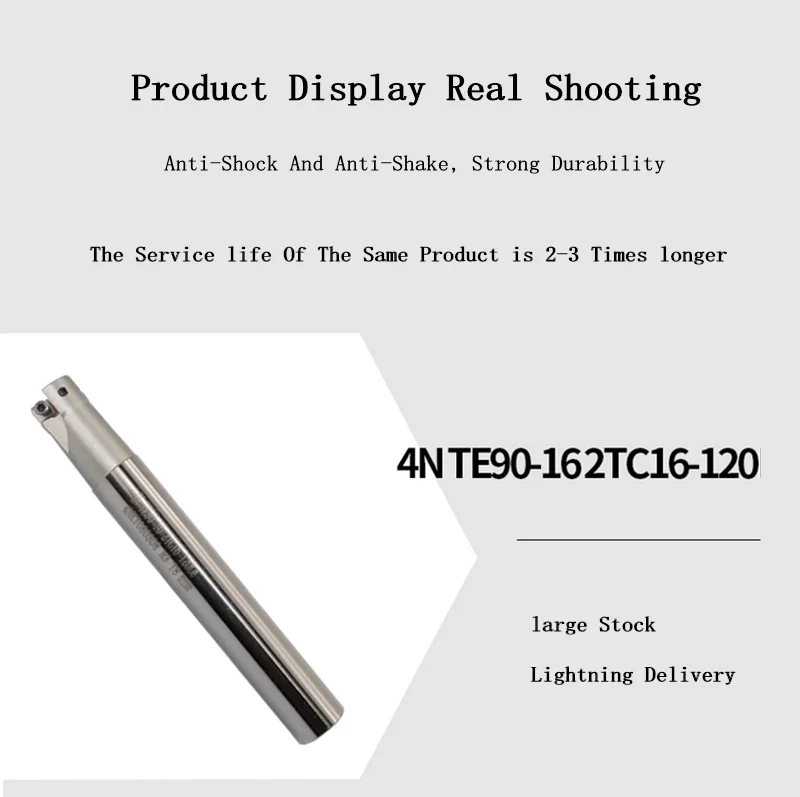

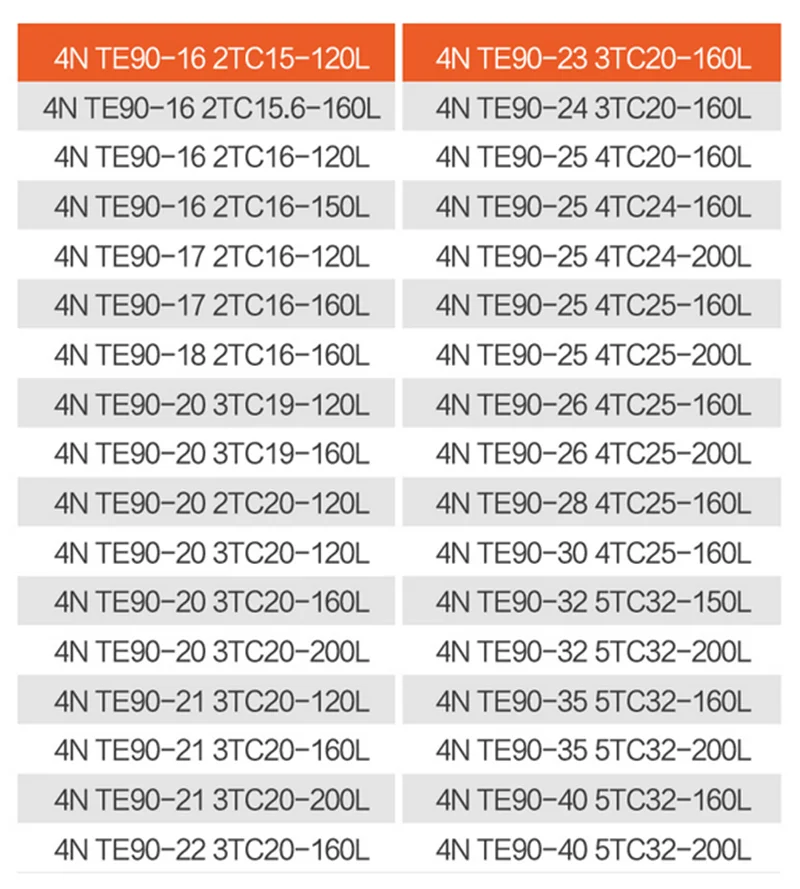

In the dynamic world of CNC machining, the right milling cutter bar can be the difference between an average job and a masterpiece. The 4N TE90 double - sided fast feed milling cutter bar, designed specifically for 4NKT carbide inserts, has emerged as a game - changer in the industry.

Unparalleled Compatibility with 4NKT Carbide Inserts

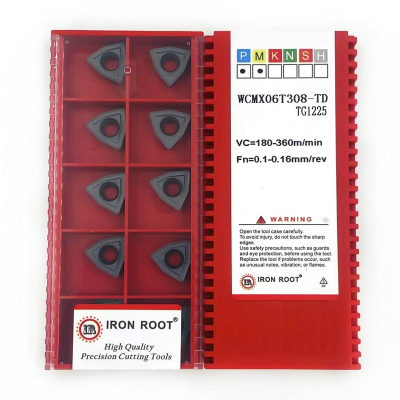

The 4N TE90 is engineered to work in perfect harmony with 4NKT carbide inserts. These inserts, known for their high precision and efficiency, are a staple in many machining operations. The 4NKT series is made from high - quality carbide material, often featuring ultrafine powder sourced from reliable suppliers. With a unique formula and advanced production technology, they offer an excellent balance between bending strength and hardness. This combination allows for sharp cutting edges that can withstand the rigors of continuous use, whether machining steel,

stainless steel,

cast iron, or other common materials.

One of the key features of the 4N TE90 is its double - sided design. This means that both sides of the milling cutter bar can be utilized, effectively doubling the lifespan of the tool. When one side starts to show signs of wear, machinists can simply flip it over and continue working. This not only reduces the frequency of tool replacements but also saves time and money.

The "fast feed" in its name is no exaggeration. The 4N TE90 is designed to operate at high feed rates, enabling faster material removal. This is crucial for high - volume production jobs where time is of the essence. By increasing the feed rate without sacrificing precision, machinists can significantly boost productivity. However, the fast feed is not at the cost of quality. The bar's design, along with the compatibility with 4NKT inserts, ensures that the surface finish of the machined parts remains smooth and free of defects.

The 90 - degree angle of the 4N TE90 is optimized for a variety of milling applications. It is particularly well - suited for shoulder milling, where it can create clean, sharp edges. This geometry also provides stability during the cutting process, allowing for more accurate machining. Whether it's roughing out a large amount of material or performing a fine finishing operation, the 90 - degree geometry of the 4N TE90 proves its versatility.

The 4N TE90, in combination with 4NKT carbide inserts, is suitable for a diverse range of applications. In the automotive industry, it can be used to machine engine blocks, transmission components, and other parts made from alloy steel or cast iron. The ability to work at high feed rates makes it ideal for mass - producing these parts efficiently.

In the aerospace sector, where precision is non - negotiable, the 4N TE90 shines. It can be used to machine parts made from stainless steel and other high - strength alloys. The double - sided design and compatibility with 4NKT inserts ensure that the tight tolerances required in aerospace machining can be met consistently.

For general metalworking shops, the 4N TE90 is a versatile addition to the tool arsenal. It can handle everything from simple steel fabrication jobs to more complex projects involving stainless steel or other hard materials. The ability to switch between roughing and finishing operations with ease makes it a favorite among machinists who need to be flexible in their work.

In addition to its performance capabilities, the 4N TE90 is also user - friendly. The process of installing and changing 4NKT carbide inserts is straightforward, even for those new to CNC machining. This simplicity reduces the learning curve and allows machinists to focus on the task at hand.

From a cost - effectiveness perspective, the 4N TE90 offers great value. The double - sided design and long - lasting compatibility with 4NKT inserts mean that users get more use out of each tool. This reduces the overall cost per part, making it an attractive option for businesses looking to optimize their machining operations without compromising on quality.

In conclusion, the 4N TE90 double - sided fast feed milling cutter bar, when paired with 4NKT carbide inserts, offers a winning combination of precision, speed, versatility, and cost - effectiveness. Whether you're in a large - scale manufacturing facility or a small - scale metalworking shop, this tool has the potential to revolutionize your milling operations.

![]()

![]()

![]()

![]()

![]()